If you've ever flipped through a bin of used records in Canada, chances are that much of what you found was pressed here. Canada's history of vinyl pressing runs deep alongside the medium's heyday. Though the factories listed on the back of your parents' rock records have long since shuttered, the steady revival of vinyl — projected to become a billion dollar industry this year — has made an all-Canadian record pressing process a reality. New plants are slated to open in Ontario and Prince Edward Island, but Toronto's Microforum Services Group will be the first to usher in a new era of Canadian-made wax.

Having produced and printed everything from floppy discs to DVDs for over two decades, Microforum kept tabs on vinyl records for years before striking a deal with Viryl Technologies. The Toronto start-up made waves in early 2016 with their design for a fully modernized and automated pressing machine — an innovation that an industry pushing half-century old machinery to its limits desperately needed.

"When we heard they were developing machines, we called them up," Microforum's VP of sales Noble Musa explains. "There was a point where [Microforum President Frank Stipo] was going there every week just to see how things were going. We made a lot of visits on top of research to see what equipment was out there."

Musa recalls that Microforum mapped out a business plan for the vinyl revival when German start-up Newbilt Machinery began manufacturing new pressing machines in late 2015. However, they lacked the automated function that Viryl's presses possessed, and Microforum's interest in the cutting-edge technology led to them buying six WarmTone presses in August of 2016.

Tucked away from the whirring optical media replication machines and printing presses of Microforum's factory floor is the company's vinyl pressing room, currently under further construction following the recent setup of a monstrous boiler and cooling system that are held in their own room. An additional room holds towering palettes of plastic-wrapped PVC pellets from England, which Musa says have delivered optimal results for both sonic and pressing qualities.

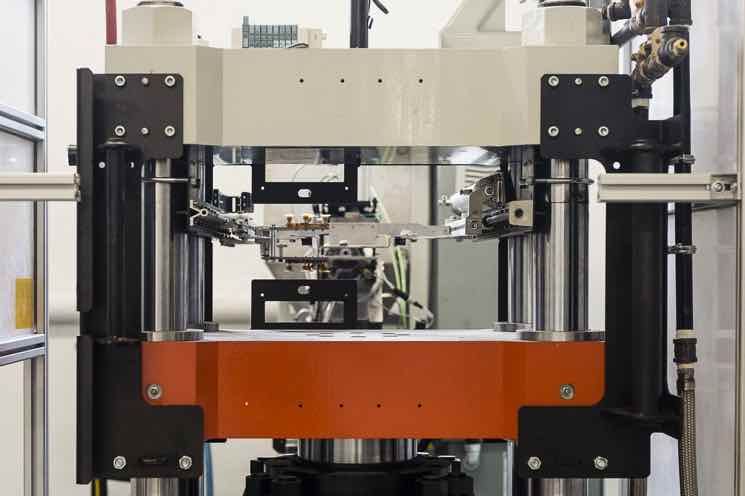

Two of Microforum's six WarmTone units have been installed, with another two set to arrive alongside their gleaming counterparts in the spring of this year. With all six installed and operating by the end of 2017, the plant will be able to pump out 24,000 records a day.

"These machines are also safer," Musa notes, gesturing at the machine's attached clear frontal enclosure, adding that one employee can easily work two pressing lines at a time. "They're self-contained, you're not standing over steam, your hands are nowhere near anything that can hurt them. That was important to us. Turn it on, push a button, and the machine goes."

Digital sensors within the WarmTone track everything from temperature to PVC type, making it easy for the plant to monitor operations and collect data that can even be sent to smartphones. The mechanical benefits also outweigh those of old machines, with Microforum and other WarmTone adopters no longer under pressure to source — or in extreme cases create — replacement parts for broken presses.

Microforum's marketing and sales manager Aine Guiney spent seven years working at Markham's Acme Pressing, which was, for a time, Canada's only pressing plant; it closed in 2007. "Back then we had old machinery, though it was a much smaller operation," she recalled. "Over time, parts would break and it could cost you thousands to make a new one."

"We had no plans to use old machinery," Musa added. "There was a plant in the U.S. that [Stipo] went to visit, and he said it looked like a mechanic shop. There were around 11 machines total, but only five running. The rest were for parts."

The manufacturing bottleneck that comes with the breakdowns has largely been vinyl's sticking point since its resurgence, with Guiney adding that labels in the United States have already begun inquiring about pressing north of the border. Montreal's RIP-V was Canada's only pressing plant from 2009 until 2015; the company opted to sell off their machines rather than invest in them further. Calgary's Canada Boy Records took up the mantle, only to suddenly close its doors in January 2017.

But before Viryl begins expanding globally and Canada's other pressing plants become operational, Microforum will drop needle to groove first. Twenty-five prototype jobs later, Musa says client reaction has been nothing but positive.

"What Viryl is doing is right up our alley," he says confidently. "We're kind of glad we waited a little bit. We think we have something here that will put us in a different league."

Having produced and printed everything from floppy discs to DVDs for over two decades, Microforum kept tabs on vinyl records for years before striking a deal with Viryl Technologies. The Toronto start-up made waves in early 2016 with their design for a fully modernized and automated pressing machine — an innovation that an industry pushing half-century old machinery to its limits desperately needed.

"When we heard they were developing machines, we called them up," Microforum's VP of sales Noble Musa explains. "There was a point where [Microforum President Frank Stipo] was going there every week just to see how things were going. We made a lot of visits on top of research to see what equipment was out there."

Musa recalls that Microforum mapped out a business plan for the vinyl revival when German start-up Newbilt Machinery began manufacturing new pressing machines in late 2015. However, they lacked the automated function that Viryl's presses possessed, and Microforum's interest in the cutting-edge technology led to them buying six WarmTone presses in August of 2016.

Tucked away from the whirring optical media replication machines and printing presses of Microforum's factory floor is the company's vinyl pressing room, currently under further construction following the recent setup of a monstrous boiler and cooling system that are held in their own room. An additional room holds towering palettes of plastic-wrapped PVC pellets from England, which Musa says have delivered optimal results for both sonic and pressing qualities.

Two of Microforum's six WarmTone units have been installed, with another two set to arrive alongside their gleaming counterparts in the spring of this year. With all six installed and operating by the end of 2017, the plant will be able to pump out 24,000 records a day.

"These machines are also safer," Musa notes, gesturing at the machine's attached clear frontal enclosure, adding that one employee can easily work two pressing lines at a time. "They're self-contained, you're not standing over steam, your hands are nowhere near anything that can hurt them. That was important to us. Turn it on, push a button, and the machine goes."

Digital sensors within the WarmTone track everything from temperature to PVC type, making it easy for the plant to monitor operations and collect data that can even be sent to smartphones. The mechanical benefits also outweigh those of old machines, with Microforum and other WarmTone adopters no longer under pressure to source — or in extreme cases create — replacement parts for broken presses.

Microforum's marketing and sales manager Aine Guiney spent seven years working at Markham's Acme Pressing, which was, for a time, Canada's only pressing plant; it closed in 2007. "Back then we had old machinery, though it was a much smaller operation," she recalled. "Over time, parts would break and it could cost you thousands to make a new one."

"We had no plans to use old machinery," Musa added. "There was a plant in the U.S. that [Stipo] went to visit, and he said it looked like a mechanic shop. There were around 11 machines total, but only five running. The rest were for parts."

The manufacturing bottleneck that comes with the breakdowns has largely been vinyl's sticking point since its resurgence, with Guiney adding that labels in the United States have already begun inquiring about pressing north of the border. Montreal's RIP-V was Canada's only pressing plant from 2009 until 2015; the company opted to sell off their machines rather than invest in them further. Calgary's Canada Boy Records took up the mantle, only to suddenly close its doors in January 2017.

But before Viryl begins expanding globally and Canada's other pressing plants become operational, Microforum will drop needle to groove first. Twenty-five prototype jobs later, Musa says client reaction has been nothing but positive.

"What Viryl is doing is right up our alley," he says confidently. "We're kind of glad we waited a little bit. We think we have something here that will put us in a different league."